Optimizing Fleet Efficiency: A Supply Chain Case Study

Challenge

A major retailer struggled with inefficiencies in its pickup and order consolidation process. Their approach relied on frequent, low-volume pickups, resulting in:

- Wasted trailer space – Small, lightweight shipments and bulky, heavy items weren’t efficiently packed together.

- High transportation costs – Single-vendor pickups led to poor trailer utilization, driving up expenses.

The retailer needed a data-driven solution to optimize pickup policies while maintaining seamless warehouse operations.

Approach

We developed a Digital Twin Model to simulate and optimize the retailer’s pickup consolidation process. Our approach included:

- Cluster Analysis – Identified key shipment types (Standard, Small & Light, Bulky & Heavy, High-Value & Heavy) to uncover inefficiencies.

- Simulation of Consolidation Policies – Tested various strategies to reduce shipment volume while maintaining service levels.

- Dynamic Calibration – Optimized pickup scheduling by factoring in weight, volume constraints, and delivery time windows.

Results

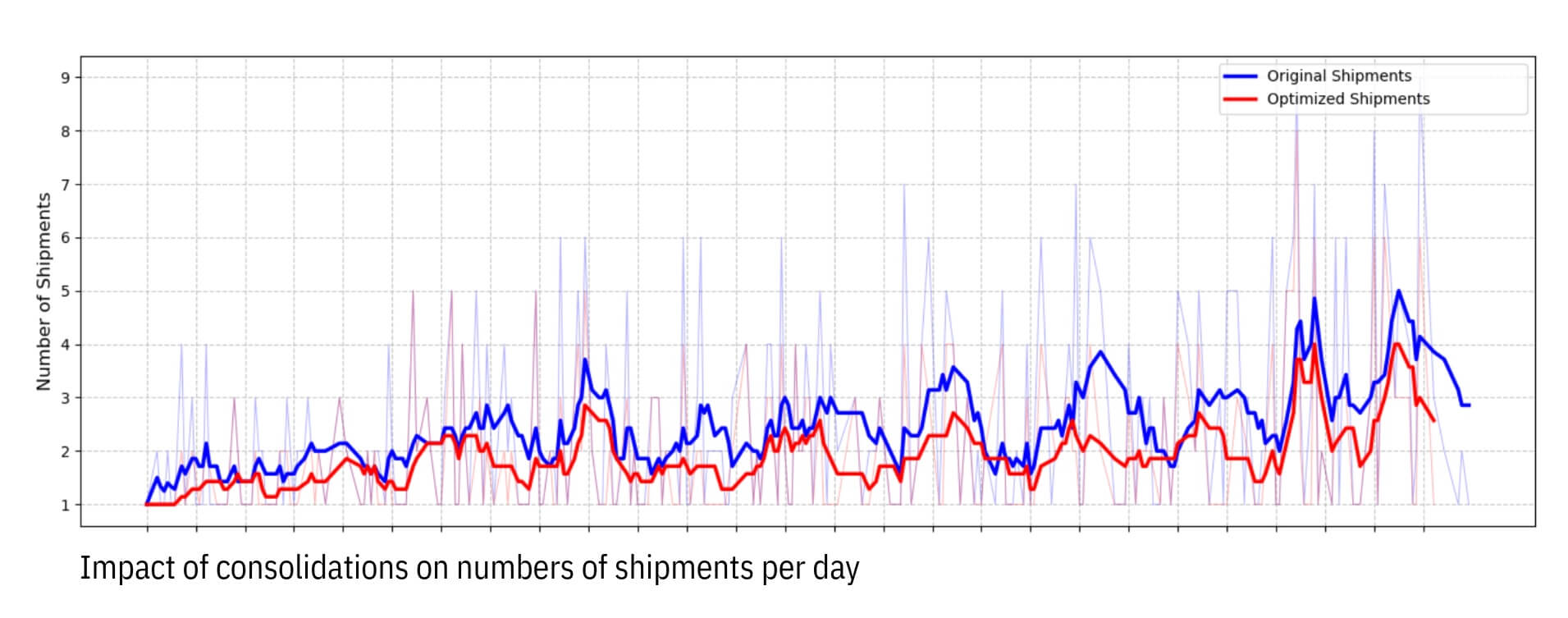

The optimization delivered tangible improvements:

✔️ 23% increase in fleet utilization – Maximized trailer space, reducing wasted capacity in small/light and bulky/heavy shipments.

✔️ 10% reduction in annual shipments – Streamlined logistics, resulting in significant cost savings.

Download our one-pager to learn more about how Process Digital Twins can transform your operations.

Optimizing Workforce Productivity: A Retail Case Study

Challenge

A leading retail chain with hundreds of sports stores needed to boost workforce productivity without increasing headcount. The executive team aimed to optimize labor allocation throughout the day and week to maximize transactions per staffing level.

A pilot initiative in a single store department revealed widespread inefficiencies across retail operations:

- Intuition-based scheduling – Staffing decisions relied on guesswork, leading to inefficiencies.

- Mismatch between staffing and customer traffic – Understaffing during peak hours and overstaffing during slow periods lowered conversion rates.

- Disconnected operational systems – POS, labor management, and traffic monitoring tools operated in silos, making optimization difficult.

These challenges underscored the need for a scalable, data-driven workforce optimization solution.

Approach

To tackle these challenges, we partnered with the retailer’s operations team to develop a Process Digital Twin Model that replicated the store’s customer journey. This model simulated:

- Key customer interactions – From the initial greeting to the final purchase, mapping touchpoints that influenced sales.

- Sales opportunity losses – Identified where and why customers exited the journey without making a purchase.

- Store-specific dynamics – Factored in buying intent, customer time tolerance, and operational constraints like item retrieval times.

This data-driven approach enabled precise workforce optimization, aligning staffing levels with real customer behavior.

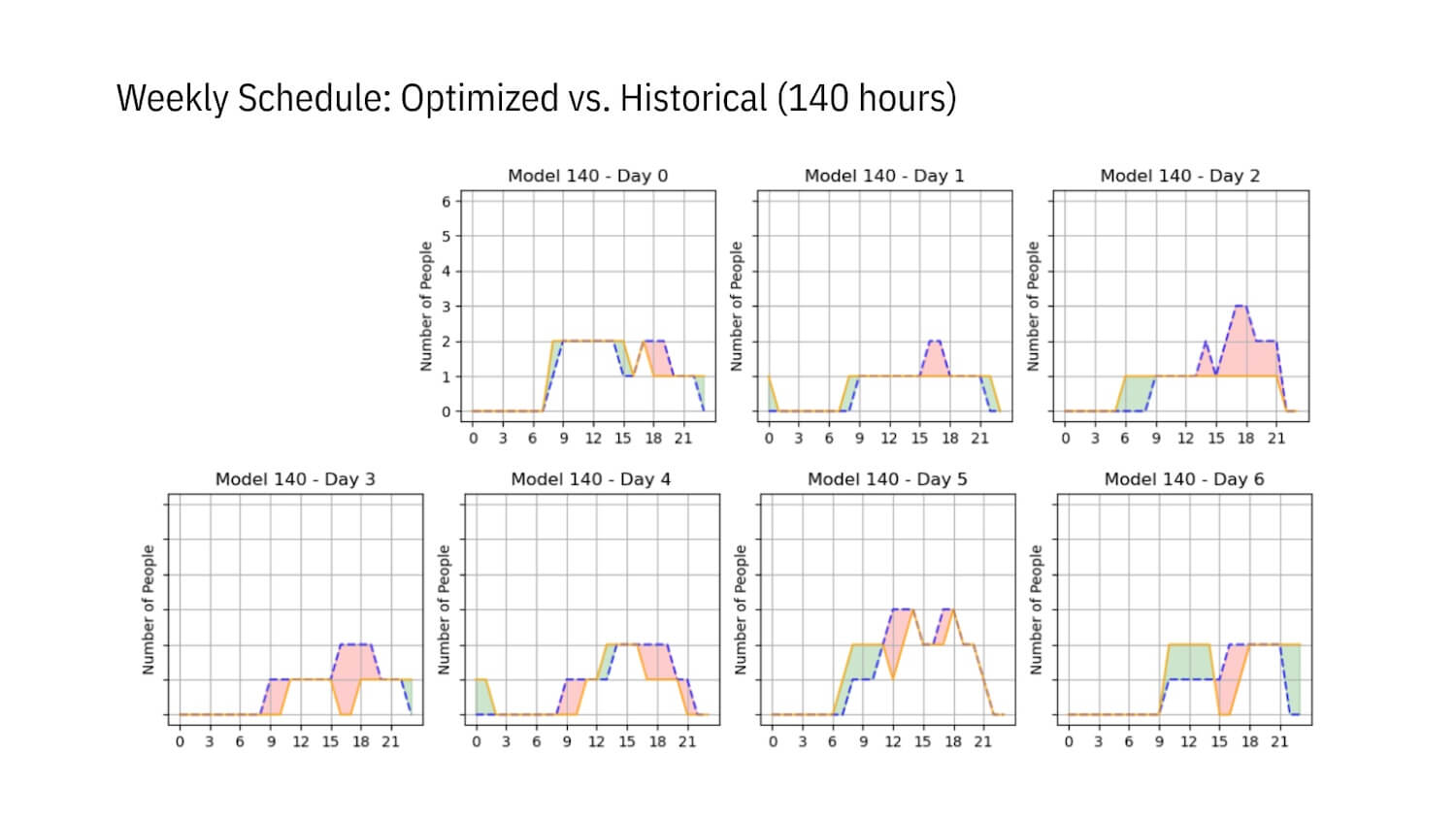

Dynamic Calibration for Scalable Insights

Unlike traditional static time studies, our approach utilized historical traffic, staffing schedules, and transaction data to dynamically infer key operational parameters. This enabled:

- Continuous adaptation – Adjusted staffing strategies in real time based on fluctuating store conditions.

- AI-driven labor scheduling – Balanced productivity with constraints like store rosters, staffing budgets, and shift policies.

- Real-time strategy updates – Allowed retailers to dynamically optimize staffing to maximize revenue, improve revenue per labor hour, or find a balance within a predefined threshold.

- Cross-store labor reallocation – Shifted workforce from overstaffed locations (where additional labor had minimal impact) to understaffed locations (where extra staffing generated the highest revenue lift).

This dynamic, data-driven approach ensured workforce optimization at scale, improving efficiency without increasing headcount.

Results

The Process Digital Twin Model delivered measurable improvements in workforce productivity and revenue optimization:

Increased Store Operational Efficiency:

✔️ Maintained transaction volumes with the same or fewer labor hours, generating significant cost savings.

✔️ Improved revenue-to-labor ratio by up to 10%, ensuring more cost-effective staffing strategies.

✔️ Enabled dynamic labor reallocation across stores, maximizing revenue per labor hour by shifting resources where they had the highest impact.

Revenue Growth Opportunities:

✔️ Stores with high untapped potential saw up to 7% growth in top-line revenue through optimized additional labor hours.

✔️ Real-time strategy updates allowed retailers to maximize revenue, optimize labor efficiency, or strike a balance—achieving sustainable, data-driven performance improvements.

Download our one-pager to learn more about how Process Digital Twins can transform your operations.

Enhancing Sales Forecast Accuracy: A Retail Case Study

Challenge

Retailers typically forecast demand using sales history, seasonality, promotions, and external factors. However, these models often overlook a key driver—planned labor allocation.

Our Digital Process Twin revealed that labor scheduling plays a crucial role in sales outcomes. By integrating labor availability into forecasting models, retailers could achieve significantly higher accuracy in predicting demand and optimizing workforce planning.

Approach

To enhance sales forecast accuracy, we extended our Digital Process Twin Model to proactively simulate store operations based on planned labor schedules. This approach incorporated:

- Traffic Prediction – Leveraged historical patterns and external factors to anticipate customer flow for the upcoming week.

- Workforce Simulation – Modeled store operations using planned labor schedules, factoring in staff availability, shift patterns, and expected customer interactions.

- Transaction Forecasting – Predicted sales outcomes by analyzing how staffing levels influenced customer flow and conversion rates, providing both shift-level and weekly transaction estimates.

Unlike conventional forecasting tools, this dynamic approach adjusted predictions based on real operational factors, including:

- Hourly staffing levels and their impact on service quality.

- Historical peak and low-traffic patterns.

- Store-specific factors like customer dwell time and buying behavior.

- Workforce efficiency variations across different store locations.

By integrating labor scheduling into sales forecasts, retailers gained a more precise, data-driven approach to demand planning.

Results

The implementation of this enhanced forecasting model delivered measurable improvements in sales prediction, workforce planning, and operational efficiency.

Higher Forecast Accuracy:

✔️Sales forecast accuracy improved by 11%, reaching up to 97%—a major leap over traditional methods.

✔️Store managers gained a proactive view of expected performance, enabling data-driven schedule adjustments before execution.

Optimized Workforce Planning:

✔️Retailers preemptively identified staffing misalignments, ensuring labor supply met customer demand before the workweek began.

✔️Shift plans were optimized based on anticipated transaction volumes, improving labor efficiency.

✔️More precise labor allocation minimized unnecessary overtime costs while maintaining sufficient coverage during peak hours.

Better Operational Control:

✔️Greater visibility into upcoming store performance empowered leadership teams to make strategic decisions in advance.

✔️Fewer last-minute scheduling changes led to improved employee satisfaction and operational stability.

✔️More accurate demand predictions enhanced inventory planning, reducing both stockouts and excess inventory.

By integrating labor scheduling into demand forecasting, retailers achieved greater accuracy, efficiency, and control, ensuring sustainable performance improvements.

Download our one-pager to learn more about how Process Digital Twins can transform your operations.

Increased engineering productivity

Summary: A leading fashion brand with an engineering team of over 200 faced significant issues. The rollout of new features took longer than expected, and the need for hotfixes post-release was becoming all too frequent. Furthermore, sub-par site performance resulted in a less-than-ideal customer experience and increased infrastructure costs.

Facing the сhallenge

The engineering leaders knew they needed a fresh, systematic approach to improve the situation. Teaming up with VSOptima, they formed a group that included professionals from Engineering, Quality Assurance, DevOps, and Infrastructure. The goal was to create a value stream model, understand the organization’s structure, and evaluate their delivery capabilities. This approach helped them uncover unseen issues in the delivery processes, team structure, and automation.

Ideas into action

Next, they ran ideation sessions to discuss potential improvements. They modeled these options and selected the most impactful ones.

Implementing change

For the next six months, VSOptima guided the engineering teams to implement changes in their DevOps practices. These changes included pre-commit feature testing, implementing an ‘Infrastructure as Code’ approach, automating environment provisioning, and strengthening automated quality gates with security testing.

Achieving results

These changes led to quicker release cycles, improved quality, and lower infrastructure costs:

- Time to Market: Reduced from 4 weeks to 1 week

- Environment creation time: Cut from 100 to just 5 hours

- Post-release issues: Reduced from 4 to fewer than 1 critical issue per month.

With VSOptima’s assistance, the fashion brand was able to streamline processes and embrace innovation. This case shows the potential of digital twinning and predictive analytics in driving operational efficiency.

Optimize patient and physician journey parameters to boost clinic efficiency.

Summary: A Clinic is a healthcare provider that treats a broad range of neurological conditions. The Clinic’s main offerings are centered around neurosurgery, ENT care, and brain health. Clinic’s surgeons achieve high efficiency in surgical procedures. Yet a substantial portion of their time is spent on non-surgical tasks, adversely affecting the organization’s revenue and profitability.

Objectives

Enhance the Clinic operational efficiency by optimizing the patient journey, targeting at least one critical performance metric:

- Time to service: consideration of the patient experience, such as respect for their time

- Service costs: need to bring healthcare costs down for employers and insurance companies

- Physician experience: help doctors enjoy the process of caregiving and deliver better work / life balance

Approach

- Mapped the patient’s trajectory from initial need recognition to post-consultation engagement and interaction, detailing essential actions undertaken by the Clinic administration, nursing, and medical personnel.

- Assessed the operational efficacy and financial health indicators throughout the patient’s path, identifying pivotal junctures where process modifications could yield substantial improvements.

- Leveraging insights from the assessment, devised strategies to enhance the patient experience and conceptualized a pilot initiative for the Clinic to implement and evaluate.

Implementing change

- Refine workflow protocols to enable Nurse Practitioners to oversee a greater number of non-surgical assessments and monitoring appointments while concurrently reducing the frequency of post-operative follow-up visits.

- Optimize the utilization of Medical Assistants and revamp the visit documentation collection protocol to secure a more efficient workflow, thereby minimizing unnecessary delays for both patients and surgeons.

Achieving results

VSOptima Developed target operating model focuses on reorganizing the patient journey that:

- accelerates the delivery of value to patients by 20% and reduces patient service costs by up to 50%

- decreases the surgeons’ involvement in non-surgical duties by more than 60%.

With VSOptima’s assistance, the clinic was able to streamline processes and embrace innovation. This case shows the potential of digital twinning and predictive analytics in driving operational efficiency in healthcare space.

See VSOPTIMA in action

Book a 25-minute demo with our team to explore VSOptima.

During our session, you can:

- Discover how to simplify intricate processes.

- Uncover ways to pinpoint inefficiencies.

- Learn how to make optimal decisions.